**Hyperbolic Glass and Steel Structure Construction Process**

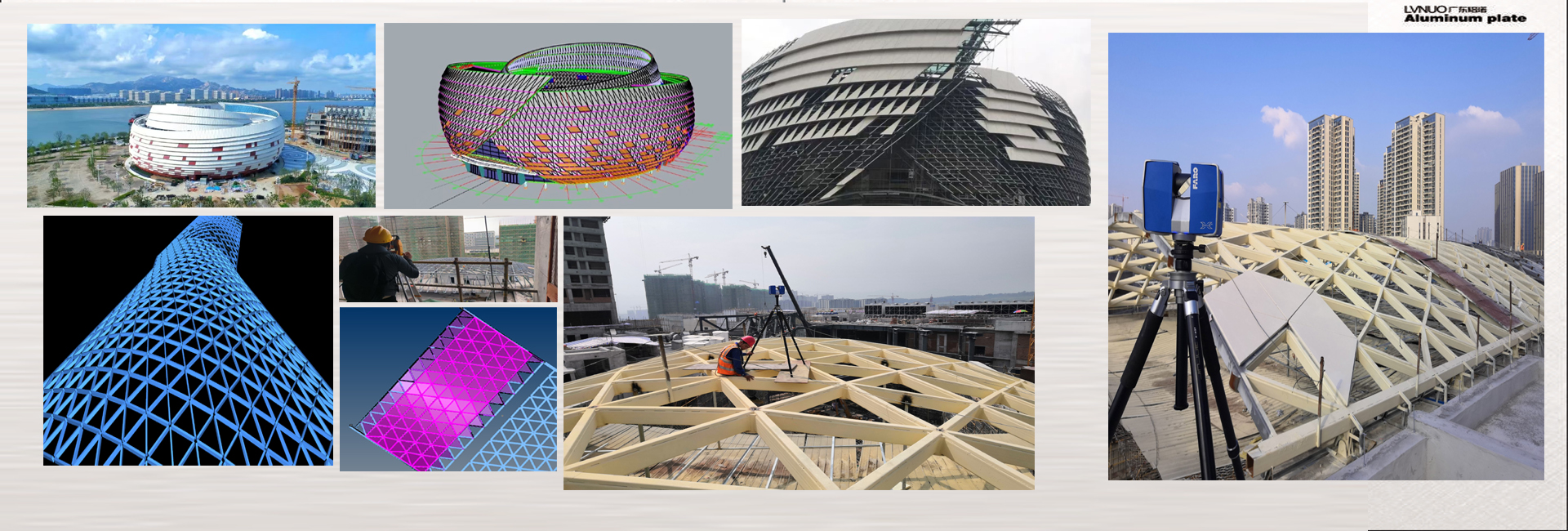

This project's curtain wall features a hyperbolic wave shape. The overall surface is complex, and conventional 2D detailing cannot meet the construction accuracy requirements. Therefore, **Rhino modeling and coordinate point layout** were used to achieve precise construction.

1. **Modeling and Segmentation**

* Create a complete wave-shaped hyperbolic surface model in Rhino and parametrically decompose the curvature.

* Divide the overall surface into machinable glass units and steel structure skeleton modules, assigning each panel a unique number.

* Output 3D coordinate data for each node as a baseline for on-site layout.

2. **Coordinate Point Layout**

* After the on-site structure is completed, use a **total station** to import the coordinate point data exported from the Rhino model.

* Layout each point by block, marking the positioning points on the steel structure installation baseline.

* Verify the accuracy of key control points (wave crests, troughs, and turning points), with an allowable deviation of ≤±3mm, to ensure overall surface continuity.

3. Steel Structure Frame Construction

* Install the main purlins according to the coordinates to ensure the overall frame forms the basic hyperbolic wave shape.

* After the main purlins are completed, arrange the secondary purlins according to the grid, and calibrate their spatial positions point by point.

* The purlins are connected to the main structure using welding and bolting, with full welds and anti-corrosion treatment.

* After completion, verify the 3D scan and compare it with the Rhino model to adjust any errors.

4. Hyperbolic Glass Installation

* Each piece of glass is custom-fabricated based on the model segmentation data (using hot or cold bending).

* After the glass panels are transported to the site, they are installed one by one in numbered order, using vacuum suction cups to lift them into place.

* Adjust the 3D position of the glass and purlins to ensure uniform gaps (≤2mm).

* Structural adhesive and weatherproof adhesive are injected into the joints to ensure force transfer and airtightness.

5. Acceptance and Correction

* Verify the entire wave curtain wall appearance through 3D scanning to ensure deviations do not exceed design requirements.

* Conduct air tightness, water tightness, and wind pressure resistance tests to ensure compliance with regulatory standards.