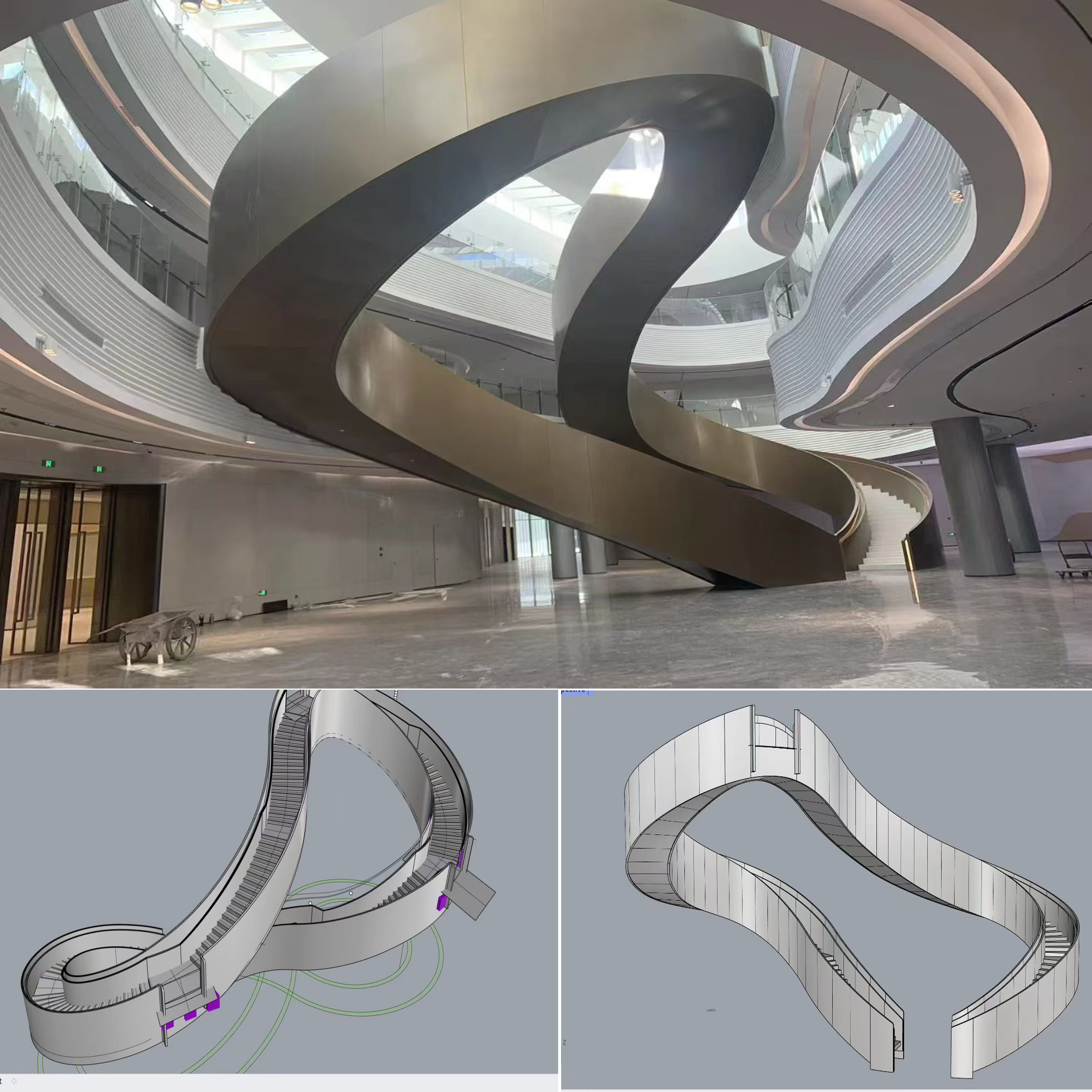

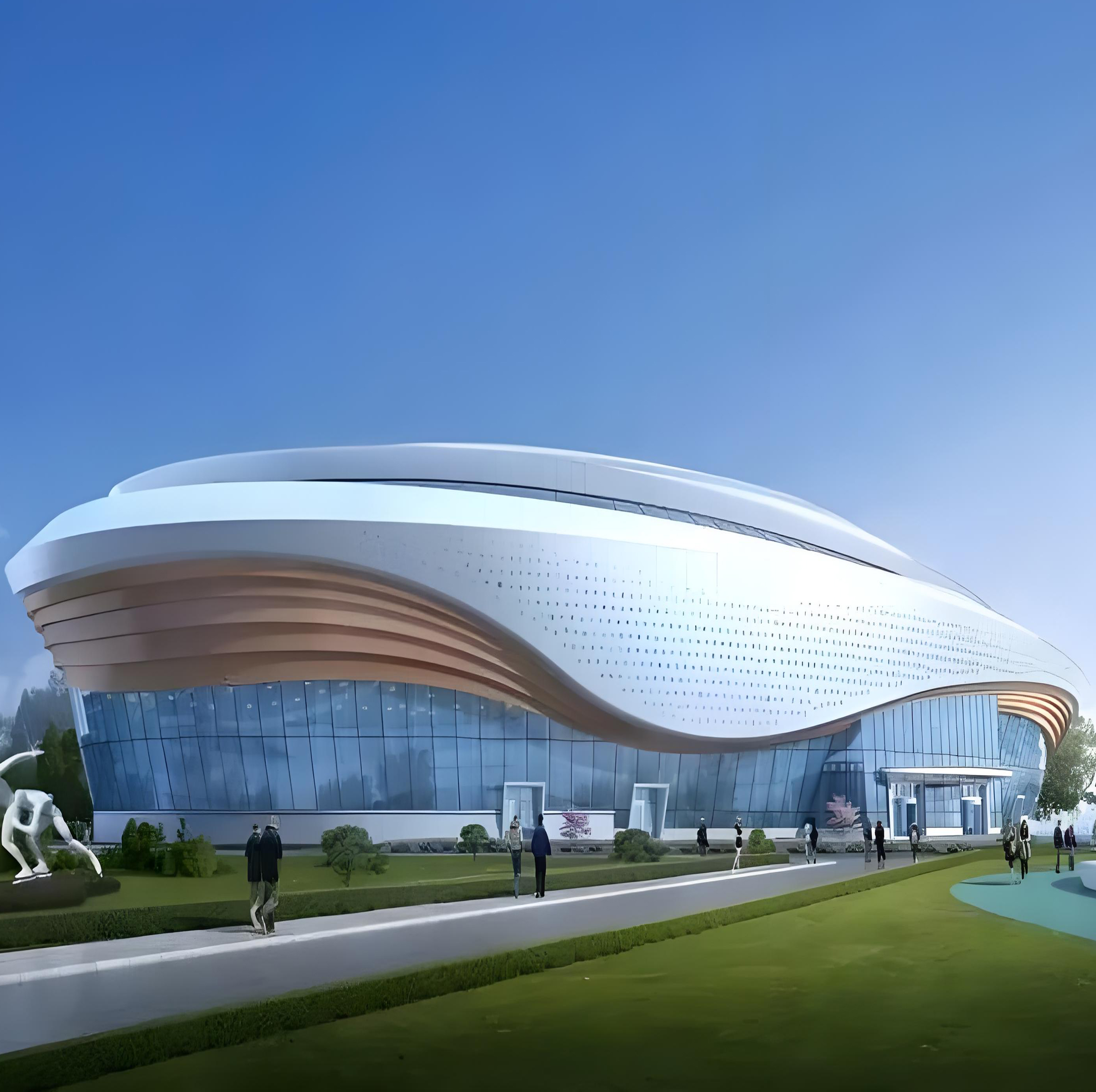

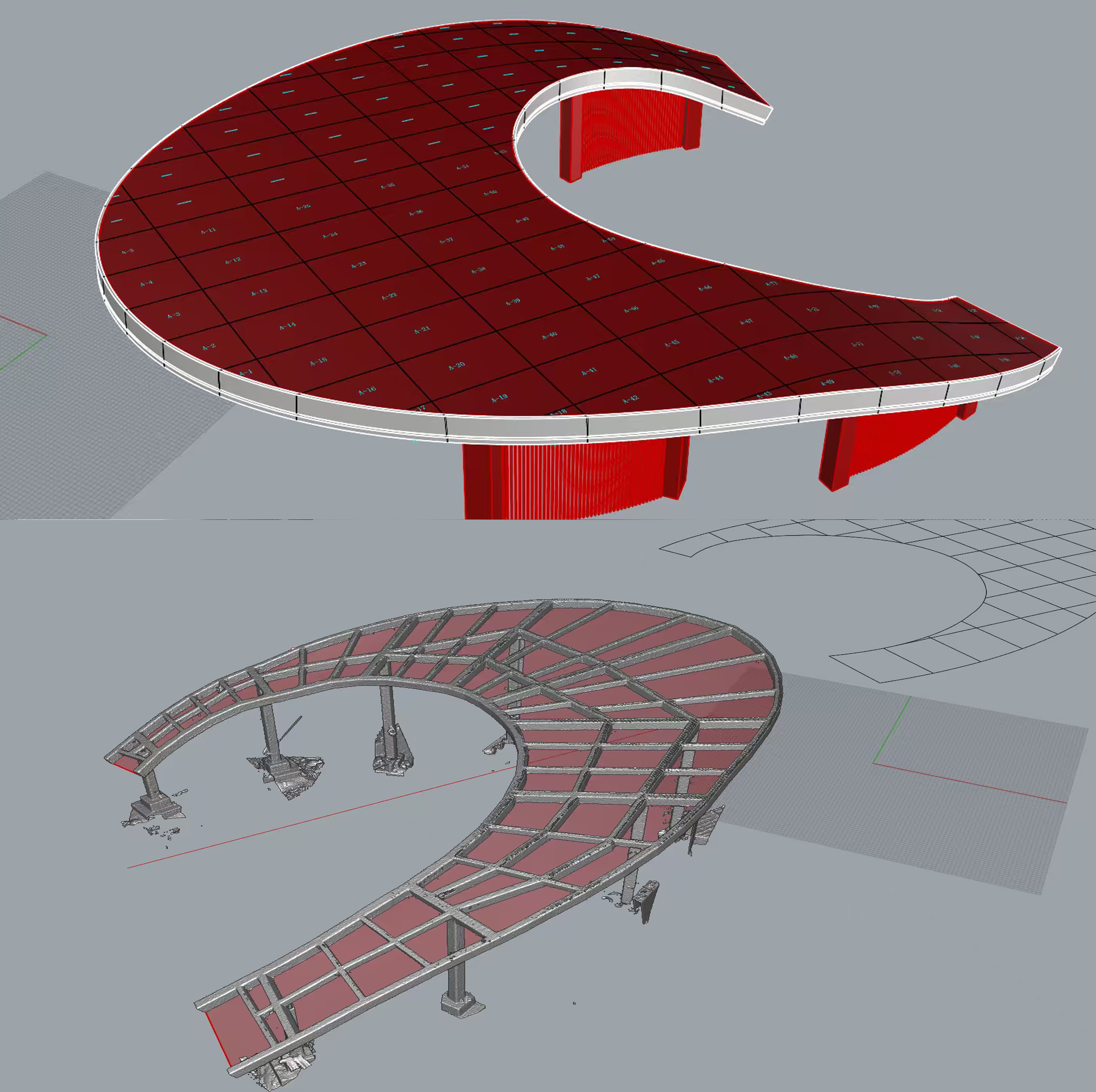

This spiral staircase features sleek aluminum cladding, combining strength with elegance. A perfect blend of modern design and architectural artistry.

view moreSpiral Staircase with Aluminum Cladding · A Masterpiece of M

This spiral staircase features sleek aluminum cladding, combining strength with elegance. A perfect blend of modern design and architectural artistry.