# **Leica Laser Scanning, Precision, and Reverse Modeling**

Leica laser scanners (usually referring to 3D laser scanners, such as the **Leica RTC360, P series, and BLK series**) use high-speed laser beams to measure the surface of an object point by point, generating high-density point cloud data. The principle is as follows:

1. **Laser Emission and Reception**

* The scanner emits a laser pulse toward the target object. The laser is reflected back upon impact.

* The instrument receives the reflected signal and records the time of flight or phase difference of the laser.

2. **Distance and Coordinate Calculation**

* Using **TOF (Time of Flight)** or **Phase-Shift**, the distance from laser emission to laser reception is calculated.

* The scanner's built-in angle encoder records the horizontal and vertical angles of the laser.

* Distance and angle are converted into **3D coordinates (X, Y, Z)** to form a point cloud.

3. **Point Cloud Stitching and Positioning**

* The data volume from a single scanning station can reach millions to hundreds of millions of points.

* Using a target sphere, a target, or a SLAM algorithm, multiple scanning stations are stitched together to create a complete spatial point cloud model.

---

## II. Accuracy and Performance

Leica laser scanners have varying accuracy depending on the model, but generally offer **high precision, wide range, and high efficiency**:

* **Ranging Accuracy**: Typically between ±1mm and ±3mm (depending on the model and environment).

* **Range**: From tens of meters (handheld BLK series) to over a thousand meters (P50 reaches >1km).

* **Scanning Speed**: Up to 1 million points/second.

* **Spatial Accuracy**: The overall error after point cloud stitching is generally controlled within ±2mm to ±5mm.

* **Environmental Compatibility**: Supports both indoor and outdoor use, with some models operating within a -20°C to +50°C temperature range.

---

## III. Reverse Modeling Process

Using point cloud data acquired by Leica laser scanning, you can perform **reverse modeling** to reconstruct complex building or structural models. The process is as follows:

1. **Data Acquisition**

* Set up scanning stations on site and complete multi-angle scanning to ensure full surface coverage.

* Use target spheres or natural feature points for registration.

2. **Point Cloud Preprocessing**

* Import into software such as Cyclone and Register360 to perform **point cloud stitching, denoising, and simplification**.

* Crop regions and classify the point cloud as needed.

3. **Point Cloud Modeling**

* Import the point cloud into software such as Rhino, Revit, AutoCAD, and 3D Max.

* Use point cloud plug-ins (such as CloudCompare, Cyclone Model, and Rhino Pointools) for **surface fitting and feature extraction**.

* Reconstruct the actual structure through **NURBS surface reconstruction** or **BIM modeling**.

4. **Model Applications**

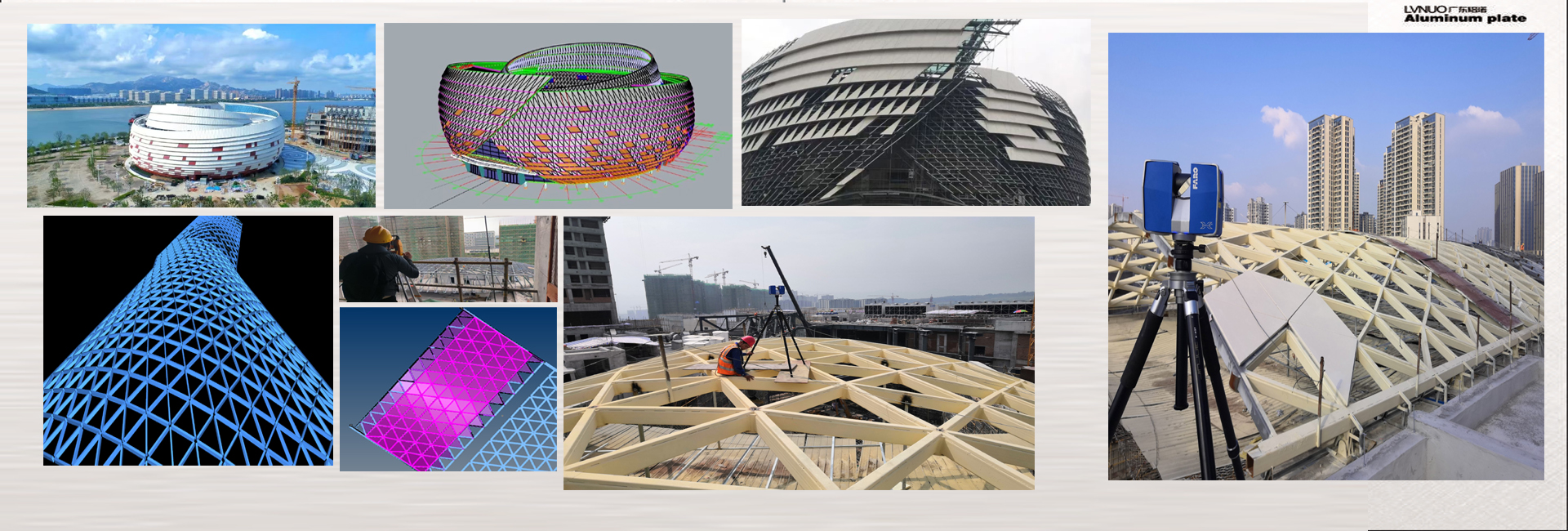

* Construction/Curtain Wall Industry: Used for curved curtain wall grid division, steel structure positioning, and construction layout.

* Industrial Manufacturing: Used for component inspection and mold reverse engineering.

* Operations and Maintenance Management: Used for digital twins and BIM operations and maintenance platforms.