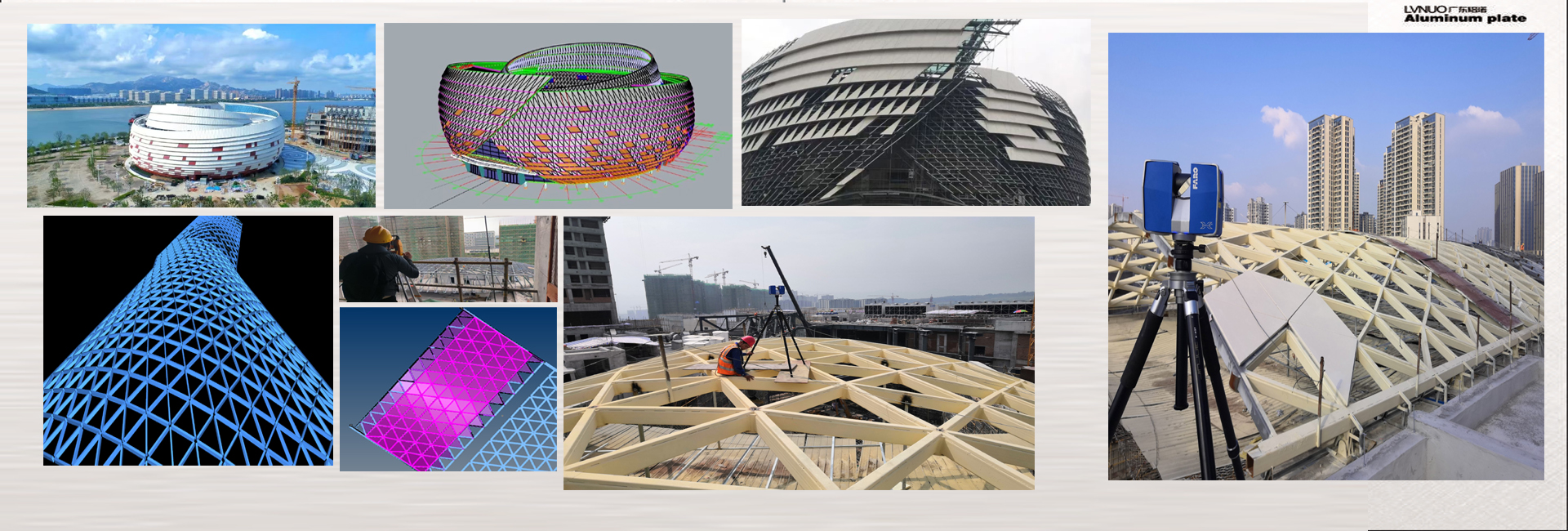

Construction Process and Key Technical Points for the Aluminum Veneer and Glass Curtain Wall Exterior of the Lintao Skating Oval in Gansu Province

I. Construction Preparation

Technical Preparation

Familiarize yourself with the construction drawings, detailed design drawings, and BIM models, and confirm the grid dimensions and joint methods.

Organize technical briefings to clarify the construction sequence and safety measures.

Develop a special construction plan based on the plateau climate (large diurnal temperature swings and strong winds).

Surveying and Layout Equipment

Use a 3D laser scanner to scan the main structure in all directions, generating point cloud data.

Create a BIM model and compare it with the design drawings to identify structural deviations.

Use a total station and theodolite for verification, and establish a 3D coordinate control system for the exterior facade.

II. Surveying and Layout and Keel Installation

Surveying and Layout

Set primary control points on the main structure and extend them to each curtain wall section to form a secondary control point grid.

Use a total station to lay out the columns and keels according to the BIM coordinates, ensuring an error of ≤±2mm.

Corners, joints, and curtain wall joints should be carefully reviewed to ensure conformance to the design grid.

Welded Embedded Parts and Column Installation

Embedded parts are connected using a combination of pre-embedded components, post-installed embedded plates, and chemical anchor bolts. The load-bearing capacity must be verified by on-site pull-out tests.

Columns must be aligned before installation, with verticality deviation ≤1.5mm/meter and total height deviation ≤5mm.

Full-weld welding is used, ensuring full welds free of porosity and slag inclusions. After welding, the welds are polished and treated with a double coat of anti-rust primer and topcoat.

Beam and Sub-Pier Installation

Beams and columns are connected using high-strength bolts or welding. Leveling is adjusted after installation.

After the purlin is installed, a reliable load-bearing system is established. Deviation Control:

Column Spacing: ±2mm

Beam Spacing: ±2mm

Mounting Surface Flatness: ≤3mm

III. Glass Curtain Wall Construction

Glass Hanger Installation

Secure the stainless steel hangers on the keel. The spacing and position must be consistent with the detailed drawing.

The hangers must be securely connected to the glass adapter, and the bolts must be equipped with lock washers.

Glass Hoisting and Positioning

Use a vacuum suction cup hoist and temporary fixing fixtures to prevent uneven force on the glass.

During the hoisting process, maintain a buffer gap between the glass and the keel to avoid direct impact.

After positioning and adjustment, secure with a pressure plate and bolts. Deviation Control:

Vertical Accuracy: ≤2mm

Horizontal Accuracy: ≤2mm

Gap Uniformity: ≤2mm

Structural Adhesive and Weathering Adhesive Application

Apply structural adhesive around the glass to ensure even force distribution.

Apply weathering adhesive to the exterior surface, with a gap depth to width ratio of 1:2.

Before applying the sealant, clean the surface and apply protective tape to prevent contamination.

IV. Aluminum Veneer Installation

Installation Process

Install panels from bottom to top and side to side, following the grid reference lines.

The panels are fixed to the secondary purlin with hangers, and the back reinforcement is welded to the mounting lugs.

Adjust the gap width to ensure uniformity (±1.5mm).

Technical Points

Avoid direct hammering during panel installation; use dedicated suction cups.

Use edge trim or special-shaped panels at the junction between the aluminum panel and the glass to ensure airtightness and visual quality.

The panel flatness deviation is ≤2mm, and the height difference of the joints is ≤1mm.

V. Quality and Safety Control

Quality Control

The entire construction process is accompanied by 3D scanning and verification, with real-time comparison of deviations between the design model and the actual construction.

Perform regular spot checks on welds, embedded component pull-out strength, and glass installation stability.

After completion, conduct a water spray test on the entire curtain wall.

Safety Measures

Glass hoisting uses dual safety lifting points, and a cordon is set up below the work area.

Workers working at height must wear safety belts and use qualified scaffolding and hanging baskets.

Gluing and installation are strictly prohibited in rainy or snowy weather.

VI. Completion and Acceptance

Appearance Inspection: The aluminum panels and glass curtain wall surfaces are flat, the color is consistent, and the gaps are uniform.

Dimension Verification: Total station and 3D scanning are used to confirm that deviations meet specifications.

Functional Testing: Air tightness, water tightness, and wind pressure resistance are tested.